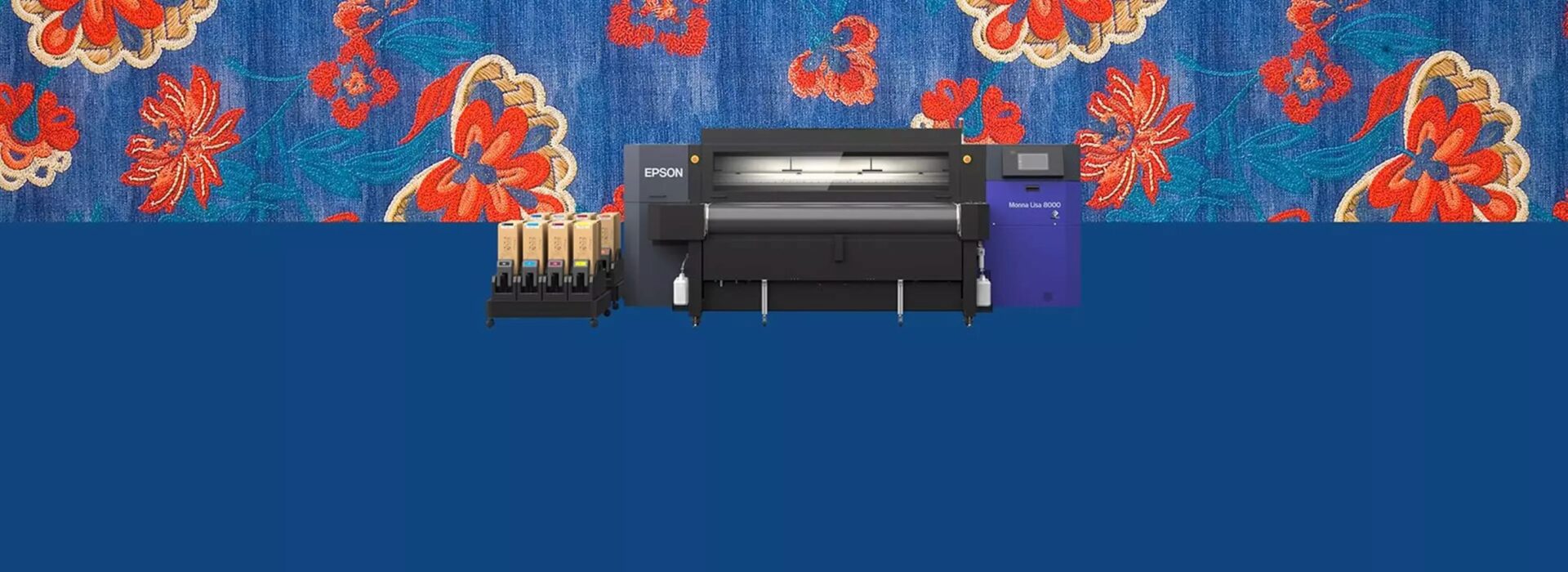

The global textile industry stands at a crossroads, navigating a significant shift towards digital processes. This move is driven by a growing demand for production methods that are swift, adaptable, and mindful of environmental impact, all without sacrificing product quality. Digital textile printing has emerged as a key technology facilitating this evolution, allowing for agile manufacturing, reduced resource consumption, and vibrant designs across a range of fabrics. Amidst this backdrop, Epson, a leader in digital imaging, has introduced a significant update to its Monna Lisa series of digital textile printers.

- Key Takeaways:

- Unmatched Productivity with Double Black Ink and PrecisionCore Technology

- Sustainable Performance with Reduced Water Usage

- Monna Lisa Quality: Powered by Epson Precision Technologies

- Engineered for Ease and Efficiency

- Environmentally Friendly Inks

- Connected for Smart Management

- Applications

- Key Specifications at a Glance:

- FAQ Section

Key Takeaways:

- Epson introduces the Monna Lisa ML-18000, a new high-volume digital textile printer.

- The ML-18000 features 18 Epson PrecisionCore Micro TFP printheads for high-speed production.

- It offers speeds up to 252 sqm/h in 2-pass mode (600 x 600 dpi).

- A double black ink configuration provides deeper, richer black tones.

- An Integrated Water Recycling Unit reduces water consumption during belt cleaning.

- Epson Precision Dot Technologies enhance print quality by reducing banding and graininess.

- The printer includes features for non-stop operation and automated maintenance.

- It uses ECO PASSPORT and GOTS-certified Epson GENESTA Reactive Inks.

- Epson Cloud Solution PORT allows for remote monitoring and faster issue resolution.

- The ML-18000 is suitable for various applications, from haute couture to home textiles.

Epson has unveiled the Monna Lisa ML-18000, the latest addition to its line of high-performance digital textile printers. This machine aims to deliver high-volume production with exceptional speed, enhanced color depth, and responsible environmental performance, addressing the changing needs of the textile and fashion printing sectors.

Unmatched Productivity with Double Black Ink and PrecisionCore Technology

At the core of the ML-18000 are 18 Epson PrecisionCore Micro TFP printheads. This configuration allows for production speeds of up to 252 square meters per hour (sqm/h) in 2-pass mode (600 x 600 dpi), all while maintaining print quality. A notable feature is its double black ink configuration, which aims to provide significantly improved black density. This enables deep, rich tones at high speeds, making it suitable for applications in fashion, home décor, and soft signage. When compared to its predecessor, the Monna Lisa ML-16000, the ML-18000 uses a higher proportion of black ink. This design choice aims to achieve improved optical density with greater cost-efficiency, particularly for dark and monochromatic designs.

The PrecisionCore technology itself represents a notable advancement in printing. Unlike traditional piezoelectric printheads that rely on mechanical pressure, PrecisionCore uses a micro-electromechanical system (MEMS) chip. This chip generates ink droplets through precise thermal changes, allowing for smaller, more uniform droplets. The result is finer detail and smoother gradations in printed output. Epson first introduced PrecisionCore in 2013, and since then, it has been integrated across various Epson products, from office printers to large-format commercial machines, demonstrating its versatility and reliability. The integration of 18 such printheads in the ML-18000 marks a substantial commitment to high-speed, high-quality industrial printing.

Sustainable Performance with Reduced Water Usage

Epson has also focused on environmental considerations with the ML-18000. The printer includes an Integrated Water Recycling Unit designed to conserve water by filtering and recycling water used in belt cleaning processes. A built-in sensor continuously monitors the level of water contamination. This helps ensure maximum recycling efficiency and aims to comply with local wastewater drainage regulations. This system seeks to reduce water consumption, meet local wastewater regulations, and minimize environmental impact. The growing global concern over water scarcity has pushed industries to re-evaluate their processes. The textile industry, historically a significant consumer of water, particularly in dyeing and finishing, is under increasing pressure to adopt sustainable practices. Epson’s approach with the integrated recycling unit aligns with this broader industry trend towards more resource-efficient manufacturing.

Monna Lisa Quality: Powered by Epson Precision Technologies

The ML-18000 integrates Epson’s Precision Dot Technologies. These include microweave and lookup table technologies, which aim to reduce banding and graininess in printed images. The printer also features multi-layer halftone technology, which randomizes halftone dot patterns to reduce visual artifacts and promote smoother gradations. Other features, such as symmetrical color alignment, accurate belt position control, and Epson Edge Print PRO X – genuine Epson RIP software that supports Adobe PDF Print Engine (APPE) with 16-bit rendering – are designed to guarantee high-speed, high-quality outputs with clarity and accuracy, which is essential for intricate designs and fine patterns.

The development of Precision Dot Technologies stems from Epson’s long history in inkjet printing. The company’s origins trace back to 1942, with the founding of Daiwa Kogyo, which later became Seiko Epson Corporation. Their early work in watch manufacturing led to advancements in precision engineering, which were later applied to printing technology. The continuous refinement of droplet placement and ink dispersion over decades has culminated in technologies like microweave, which precisely controls the movement of printheads and the placement of ink droplets to prevent noticeable lines (banding) in prints. Lookup tables, on the other hand, are mathematical models that optimize color reproduction by mapping input color values to the printer’s specific ink set, aiming for consistent and accurate color output.

Engineered for Ease and Efficiency

The ML-18000 is built for continuous operation. It features a dual 10-liter ink system, high-efficiency cleaning mechanisms, and automated maintenance tools. These tools include auto nozzle verification technology, fabric wiper cleaning, a fluff blower system, an ink mist extraction system, and auto calibration powered by an integrated RGB camera. These features aim to ensure consistent print quality while minimizing downtime. For industrial settings, minimizing downtime is a critical factor in profitability. Every minute a machine is not printing, it represents a lost opportunity for production. The automated maintenance features in the ML-18000 are designed to address this directly, allowing operators to focus on production rather than manual upkeep.

Environmentally Friendly Inks

The ML-18000 uses Epson GENESTA Reactive Inks. These inks are ECO PASSPORT certified, meeting globally recognized standards for environmentally responsible textile printing, and are GOTS-approved by ECOCERT. These inks aim to deliver color reproduction while minimizing environmental impact. The certifications, such as ECO PASSPORT by OEKO-TEX and GOTS (Global Organic Textile Standard), are important benchmarks in the textile industry. ECO PASSPORT ensures that textile chemicals, including inks, are safe for human health and the environment. GOTS is a broader standard for the processing of organic textile fibers, which includes strict environmental and social criteria. The use of certified inks by Epson underscores a commitment to producing textiles that meet increasingly stringent environmental regulations and consumer expectations.

Connected for Smart Management

The printer is supported by Epson Cloud Solution PORT, which allows users to monitor printer performance remotely from a PC or mobile device. This aims to maximize productivity by providing real-time visibility into workflow and enabling Epson’s service teams to diagnose issues remotely, leading to faster resolution and less disruption. The rise of IoT (Internet of Things) in industrial settings has transformed how equipment is monitored and maintained. Cloud-based platforms like Epson Cloud Solution PORT leverage this connectivity, providing businesses with data-driven insights into their operations. This proactive approach to maintenance and performance monitoring can significantly reduce unforeseen breakdowns and optimize overall equipment effectiveness (OEE).

Applications

The ML-18000 is suitable for producing prints on various fabrics, including silk, cotton, polyester, and blends. Its versatility makes it suitable for diverse markets such as haute couture, fast fashion, home textiles, and sportswear. The ability to print on different fabric types with the same machine broadens its appeal to a wider range of textile manufacturers. For example, in haute couture, the demand is for intricate, limited-run designs on luxurious fabrics. In fast fashion, speed and adaptability to changing trends are paramount. For home textiles, durability and colorfastness are key. The ML-18000’s stated versatility suggests it can address these varied demands.

Key Specifications at a Glance:

- Printheads: 18 Epson PrecisionCore Micro TFP printheads.

- Print Speed: Up to 450 sqm/h (300 x 600 dpi, 1 pass), 252 sqm/h (600×600 dpi – 2 pass), 162 sqm/h (900×600 dpi – 3 pass).

- Resolution: Up to 1200 dpi.

- Print Width: 185 cm.

- Ink Colors: 8 (Black, Cyan, Magenta, Yellow, Grey, Red, Blue, Orange, Crimson).

- Ink Capacity: Dual 10-liter tanks.

- Inks: GENESTA Reactive Inks (ECO PASSPORT and GOTS-certified).

FAQ Section

Q1: What is the primary benefit of the Epson Monna Lisa ML-18000 for textile manufacturers?

A1: The ML-18000 aims to provide high-speed, high-volume digital textile printing with enhanced color depth and reduced environmental impact, making it suitable for industries needing quick production and sustainability.

Q2: How does the double black ink configuration improve print quality and cost-efficiency?

A2: The double black ink configuration allows for significantly improved black density, creating deep, rich tones even at high speeds. It uses a higher proportion of black ink for improved optical density with greater cost-efficiency, especially for dark and monochromatic designs.

Q3: What makes the Monna Lisa ML-18000 an environmentally responsible choice?

A3: The ML-18000 features an Integrated Water Recycling Unit that conserves water used in belt cleaning. It also uses Epson GENESTA Reactive Inks, which are ECO PASSPORT and GOTS-approved, meeting standards for environmentally friendly textile printing.

Q4: Can the ML-18000 print on different types of fabric?

A4: Yes, the ML-18000 is designed to print on a variety of fabrics including silk, cotton, polyester, and blends, making it adaptable for diverse applications from fashion to home textiles.

Q5: How does Epson Cloud Solution PORT assist in managing the ML-18000?

A5: Epson Cloud Solution PORT enables users to monitor printer performance remotely from a PC or mobile device. This real-time visibility helps maximize productivity and allows Epson’s service teams to diagnose issues remotely, reducing downtime.